by Michael Smith (Veshengro)

Making local woods work for community enterprises

by Michael Smith (Veshengro)

Fifty communities across the UK will receive support to transform unmanaged woodland into opportunities for jobs, leisure, education and services and to improve the health and wellbeing of local people.

The Big Lottery Fund is awarding £1,151,111 to the Plunkett Foundation for its Making Local Woods Work project. The pilot project, due to launch later this year, will help people to create social enterprises in local unmanaged woodlands so they can grow into sustainable businesses, creating new areas of employment and training to benefit their communities. The opening up of much-needed access to the natural environment will not only provide opportunities for economic growth, but better engagement with the outdoors will result in better health and wellbeing for those involved.

According to the Forestry Commission, 47 per cent of woodland are unmanaged or under-managed* which can threaten the variety of plant and animal life. Many bird and plant species have been in decline in recent years**. Active woodland management could preserve and increase the biodiversity of these habitats and increase wood fuel production.

Woodland social enterprises are beginning to emerge as a way of tackling a wide range of issues and there is growing evidence of local people successfully using their skills and ideas to set up businesses which have been effective in improving communities.

One example is Hill Holt Wood in Lincolnshire which provides training for young people who have been referred by agencies because they are excluded from school or are unemployed. The woodland also attracts more lone visitors, particularly women, due to the presence of volunteers performing activities including coppicing, woodcraft and charcoal manufacturing. Revenue is also achieved through its cafe and green burials. A further example is Blarbuie Woodland Enterprise in Argyll which has provided residents of the Bute long stay hospital, access to the adjacent woodland, activities such as arts and crafts, wildlife walks, training and employment opportunities.

Making Local Woods Work will provide training, volunteering and employment opportunities to 500 people tackling unemployment, social isolation and poverty. It will support, advise and train 50 groups across the UK to become woodland social enterprises involving study visits, training in asset transfers, financing, asset acquisition, land brokerage, woodland management and business planning. It will also deliver training and knowledge sharing events to 200 groups looking at setting up their own woodland social enterprises.

The project will be delivered in partnership with the Forestry Commission, The Woodland Trust, Grown in Britain and other partners.

Improving the availability and quality of knowledge to such a large body of people will help to bring about wide-scale improvements in the ability of groups to set-up local woodland social enterprises. Evidence of the project’s impact and sharing of the learning will be used to influence future practice of woodland social enterprises and also woodland management in general.

Peter Couchman, Chief Executive of the Plunkett Foundation, said: “We are absolutely delighted to announce that, thanks to the Big Lottery Fund, we will be able to support 50 woodland social enterprise pilot projects across the UK over the next three years. This important work will help to support a range of social enterprises to bring woodlands into active management, increase their use and ultimately help more people to enjoy and benefit from woodlands. We’re excited to be working with both new and familiar partners on this project.”

Peter Ainsworth, Big Lottery Fund UK Chair, said: “There aren’t many woodland social enterprises around yet, but where they do exist they have a great record of promoting skills and employability. It’s exciting to be able to support this initiative which aims to improve the quality of life of those directly involved and also make woodlands more accessible and better looked after for the benefit of all.”

*Forestry Commission Sustainable Forest Management spatial data.

**The population of willow tits in the British Isles declined by 91 per cent between 1967 and 2010, the pearl bordered fritillary butterfly recently declined 42 per cent over ten years, and 56 of 72 woodland ground flora species declined between 1971 and 2001. RSPB.

Making Local Woods Work is a project led by the Plunkett Foundation involving partners the Woodland Trust, the Forestry Commission, Hill Holt Wood, the Community Woodland Association, Llan y Goedwig, the National Association of AONBs, Locality and Shared Assets. The partnership has a range of skills and experience including social enterprise development, community ownership and management of assets and woodland management.

The term “about time” does very much come to my mind with regards to things like this finally happening but we need more of this. In fact we need all unmanaged and under-managed woods in this country (and not just this country alone, that is for sure) to be brought (back) into proper management and wherever possible this should be coppice management.

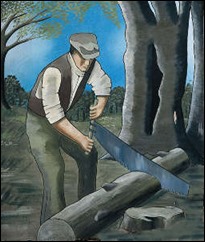

So far we are seeing way too little of this happening and often this is due to the opposition from certain people in the environmental movement who suffer from cognitive dissonance when it comes to woods and trees and the management of woods. They believe that cutting any tree, for whatever reason, harms the trees and the environment, which is not the case, especially not as far as coppicing is concerned. In fact coppice management benefits all sides.

Further reading:

© 2015

For more on woodland management and especially coppicing and why, etc. see “Managing our Woods”, a small book that explains the whys and wherefores of managing our woods in this way and calls for us to return to that way.