by Michael Smith (Veshengro)

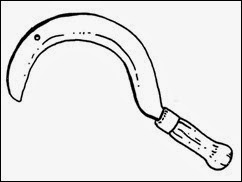

A good old-fashion sickle, sharp and perfectly weighted, is a tool just made for the job of clearing vegetation from around the trees. It given the user total control and thus does not damage the bark of the tree as often does the use of a powered grass trimmer (strimmer) and requires no guards to be placed around the trees either.

The scythe, too, is making a comeback in countryside management, and so it should. The billhook is another one of those tools that just cannot be beat when working in the management of woodlands and the countryside.

Even when it comes to felling in small woodland management operations the crosscut saw, one man or two man, will still, with the exception of the sneding of the branches, often beat the chainsaw and especially as far as noise and other pollution is concerned.

The design of the sickle, basically, has changed little since the Middle Ages and even before, though many different kinds for different purposes, much like with the billhook and the scythe, can be had. The principle, however is and remains the same. The differences are things such as sweep and curve of the blade or serrations on them, such as some of the Indian and Japanese ones have.

The good thing about a sickle is that it does not require much tuition to use it, more intuition, unlike the scythe, which does need a little skill that needs acquiring so as not to injure oneself (or others). Even the billhook requires more acquired skill than dos the sickle. Keeping it sharp, in the same was as with regards to the billhook and the scythe, is a different kettle of fish and that does take some learning.

The sickle can be used for many cutting tasks from cutting away vegetation from around trees and here especially saplings without the risk, unless one is not careful, of cutting them off or damaging them, as is often the case with the use of a strimmer, to harvesting standing crops. And, before the advent of the scythe that was what the sickle in many a form was used for also.

I, for one, love using these tools, a real link to the history of countryside workers, as they are effective and also efficient and require little to no real maintenance, other from sharpening and keeping them clean.

© 2013